MBR

o MBR (Membrane Bio Reactor)

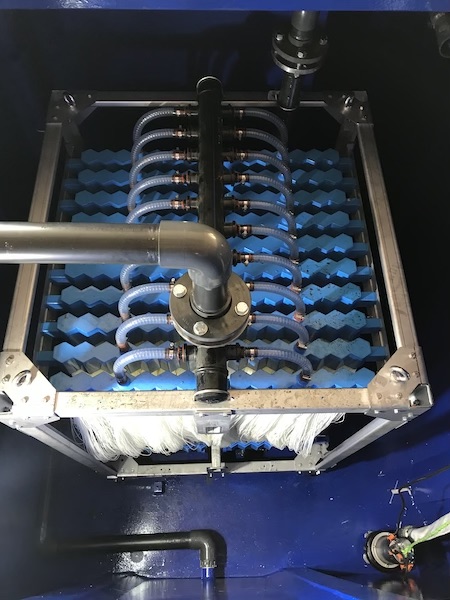

Membrane bioreactor (MBR) units, which is another process used for wastewater treatment by Coşkun Arıtma A.Ş., are up-to-date and technological products with high efficiency in water treatment. Membrane bioreactor (MBR) is widely used as an efficient compact technology for municipal and industrial wastewater treatment. The process is a combination of biological treatment of suspended solids (aeration), usually activated sludge, membrane filtration cassettes, typically low pressure microfiltration (MF) or ultrafiltration (UF) membranes. Membranes are used to fulfill the solid-liquid separation function of oxygen-enriched wastewater. In activated sludge plants, this is traditionally accomplished using secondary and tertiary cleaners in conjunction with tertiary filtration. There are two general types of MBR systems, which are vacuum (or gravity operated) and pressure operated systems. Vacuum or gravity operated systems are immersed and normally use hollow fiber or flat sheet membrane cassettes mounted in bioreactors or a subsequent membrane tank. Pressure operated systems are in-tube cartridge systems located outside the bioreactor. "MBR System" must be a complete and integrated membrane unit (subsystems) with the necessary components to keep the process running as intended. MBR system usually consists of five zones as Pretreatment, Anoxic unit, Aerobic unit, Compact Membrane Filtration Unit and Disinfection unit.

Preferred

sectors:

· Food and Drink

· Gasoline Industry

· Pharmaceutical Industry

· Slush and Paper Industry

· Textile Industry Waste

· Storage Area Infiltration Water

· Ship Waste

· Industrial and Municipalities

MBR operation and maintenance

In MBRs, the flow reduction is mainly caused by the pollution of the membranes and the blockage of the holes on the membrane surface:

By `pollution` is meant coating the membrane surface or clogging the membrane pores with dissolved, colloidal or fine solids. Such blockages are removed by physical and chemical cleaning cycles (backwashing).

By "blockage" is meant the accumulation of gross solids in or at the entrance of membrane channels. Blockages inside the channels are sometimes called `activated sludge or dead bacteria`.

Advantages of MBR,

Secondary treatment or existing tertiary filtration is generally 30-50% smaller, occupying less space than an equivalent conventional activated sludge plant. It is a modular process that provides exceptional treatment quality, expandable capacity and ease of configuration flexibility that can meet the most solid water quality requirements. It requires robust and reliable operation and low disinfection need.

High quality treated water

The permeability of the membrane (the pore size) (<0.5 µm), can be named as the treated wastewater has very high clarity compared to other alternative processes and has a reduced pathogen density.

The MBR process provides a high quality of treated and disinfected treated water that can be discharged to sensitive discharge points or recovered for operations such as urban irrigation, city cannulation line or toilet reservoir. In addition, the output water is high quality so that it can be applied immediately to reverse osmosis process.

For more information:

or

Tel: +90 262 644 0 808

2020 COŞKUN ARITIM A.Ş.

Wastewater and process water treatment. Designing a treatment plant with

the advantage of the manufacturer, production, installation, spare part and post-delivery

service. Turnkey facilities.

Tel: +90 262 644 0 808 info@coskunaritma.com

Key words

Wastewater treatment plants, compact treatment, how treatment works, water treatment, package treatment, continuous system, batch activated sludge system, biological treatment, septic tank treatment, treatment services, technical service, MBBR, MBR, SBR

+90 262 644 0 808

+90 262 644 56 18

info@coskunaritma.com